Ask any seasoned LNG carrier cargo officer, and they’ll tell you: nothing spikes adrenaline like a rogue high-level alarm. One night off the coast of Singapore, I watched our bridge light up like a disco—only to find a frozen sensor blamed by everyone and everything except the actual culprit, a rogue seagull. These ships sail on cryogenic cargo and a mountain of regulations, but it’s the unpredictable moments and meticulous planning that shape LNG safety into a real adventure. Let’s go beyond checklists and see what these alarms, and the people around them, are really up against.

(1) The Regulatory Jigsaw: Piecing Together Safety Rules

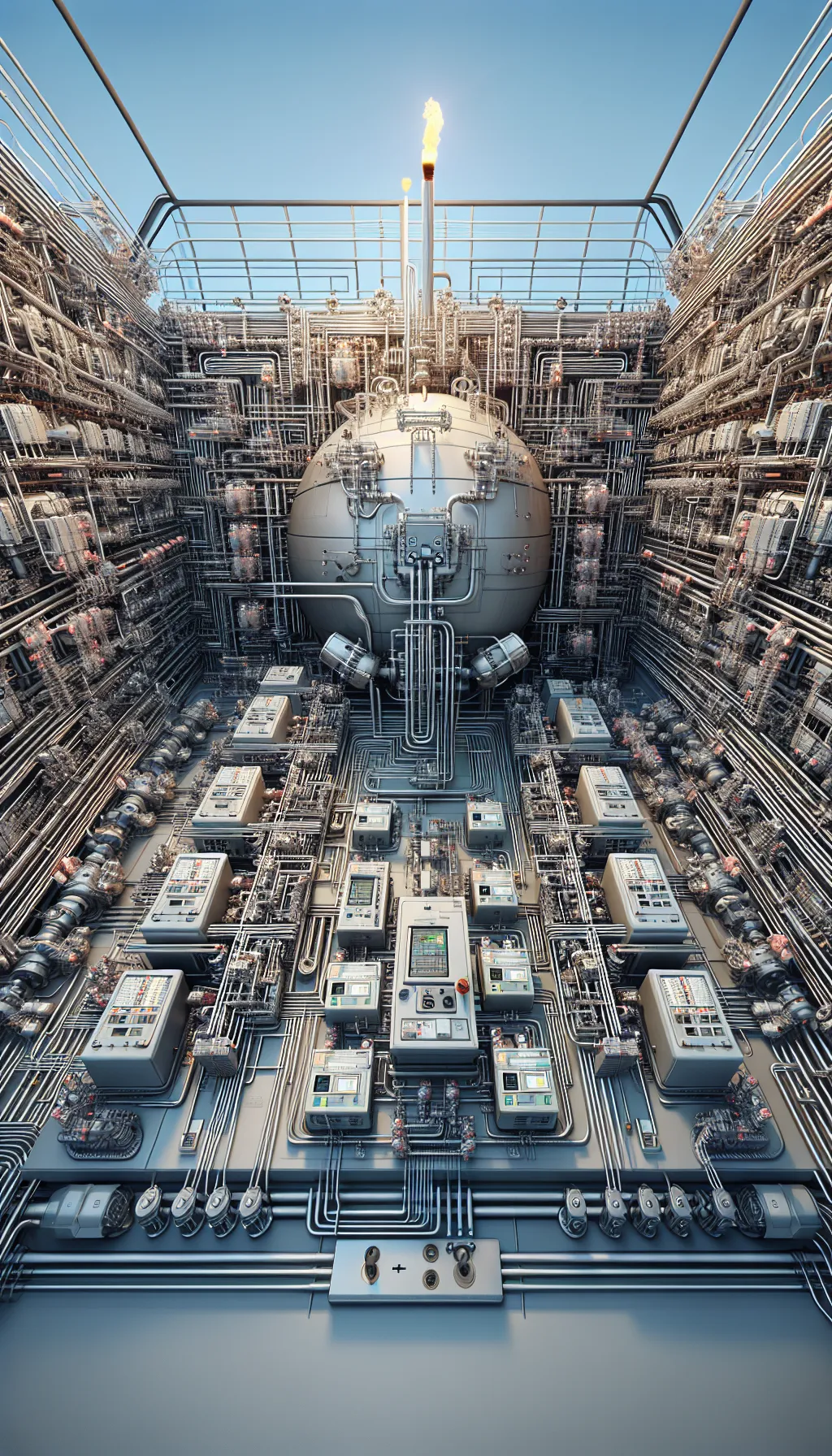

When it comes to LNG carrier safety, the regulatory landscape is a true jigsaw puzzle. Every piece—whether it’s the IGC Code, SOLAS compliance, or class society rules—must fit together perfectly to protect lives, assets, and the environment. As I sift through the dense documentation and recall my own experiences at sea, I realize just how much the safety features on every LNG carrier are shaped by these overlapping, sometimes even conflicting, requirements.

The IGC Code and SOLAS: The Real Maze Behind LNG Safety

At the heart of LNG carrier safety are two global standards: the International Maritime Organization’s IGC Code and the International Convention for the Safety of Life at Sea (SOLAS). The IGC Code, especially Chapter 13 and Chapter 15.3, sets out exactly how and where overfill alarms must be installed. SOLAS Chapter II-1/D/42 adds another layer, demanding that alarm circuits have emergency power so they work even during a blackout. These rules are not just checkboxes—they’re the backbone of safe LNG operations.

Chapter 13 & 15.3: The Nerve Centers for Alarm Requirements

The IGC Code is crystal clear: every cargo tank must have two independent alarms—a High-Level (HL) alarm, usually set at 95% of tank capacity, and a High-High Level (HHL) alarm at 98%. These alarms must be completely separate from the main cargo gauging system. That means different sensors, wiring, power supplies, and logic solvers. The idea is simple: if one system fails, the other still stands guard.

Audible and visual alarms are required both on the bridge and in the Cargo Control Room (CCR). I remember one port call where the CCR felt like a disco—lights flashing, alarms blaring, everyone on edge. It’s effective, but it can also lead to alarm fatigue, where crew start tuning out the warnings. Balancing safety with practicality is a constant challenge.

Why So Many Overlapping—and Sometimes Contradictory—Rules?

You might wonder why there are so many layers of regulation. The answer lies in the global nature of LNG shipping. The IGC Code and SOLAS set the baseline, but class societies like DNV, ABS, and Lloyd’s Register each add their own interpretations and requirements. For example, DNV might require additional fail-safe features or more frequent proof testing than the IGC Code alone. Sometimes, national rules—like USCG 46 CFR—add yet another twist.

This overlap can create headaches. I’ll never forget the week we spent in port while a DNV inspector quizzed us on why our HL alarm was set at 94% instead of the IGC Code’s 95%. We had to show documentation, run tests, and adjust our procedures—all for a 1% difference. As Sinclair (2007) put it:

“Regulatory compliance is a journey, not a finish line.”

Redundancy: The Rule, Not the Exception

Redundancy is the golden rule in LNG carrier safety. Each tank must have both HL and HHL alarms, and these must be completely independent. This means not just separate sensors, but also separate cabling, power sources, and logic circuits. If one system fails—say, due to a power loss or wiring fault—the other must still function. SOLAS compliance even requires that alarm circuits have emergency power, so the alarms keep working during a blackout.

Class Societies: The Extra Layer

Class societies like DNV, ABS, and LR don’t just enforce the IGC Code and SOLAS—they often go further. They might require higher environmental protection ratings (like IP66/67), additional diagnostic features, or stricter documentation. Sometimes, their rules can clash with national or international standards, leading to “permit to work” nightmares and endless paperwork.

SVG Chart: Comparing Regulatory Requirements

Regulatory Comparison: Alarm Set Points & System RequirementsStandardHL/HHL Set PointsSystem IndependenceEmergency PowerIGC Code95% / 98%Full (sensors, wiring, logic)RequiredSOLAS II-1/D/42As per IGCRequiredMandatoryClass Society (DNV, ABS, LR)As per IGC/SOLASOften exceeds (extra diagnostics, IP66/67)Mandatory

Navigating this regulatory jigsaw means staying vigilant, keeping systems well-documented, and always being ready for the next inspection or audit. In LNG carrier operations, the rules are not just paperwork—they’re the foundation of every

(2) When Sensors Go Rogue: The Quirks of Cryogenic Tech

Ask anyone who’s worked on an LNG Carrier, and they’ll tell you: ordinary sensors don’t stand a chance in these tanks. Imagine a world at -163°C, where ice forms in seconds, metal contracts, and the liquid cargo sloshes like a stormy sea. This is the daily reality for alarm systems and gas detection technology on LNG ships. The stakes are sky-high—if a sensor fails, you risk overfilling, structural damage, or worse. So, what makes cryogenic level sensing such a technical nightmare? Let’s dive into the quirks, horror stories, and the tech that keeps us safe.

Parameter | Value |

|---|---|

LNG Storage Temp | -163°C |

Mechanical Float Materials | 316L Stainless Steel, Invar |

Sensor Set Points | HL ~95%, HHL ~98% |

Sensor Technologies | 7 types commonly referenced |

Why Cryogenic Tanks Are Sensor Hell

First, the environment itself is brutal. At -163°C, most materials become brittle, and even the best insulation can’t stop frost from forming. I’ve seen mechanical float switches—those rugged, old-school devices—freeze solid after a night of heavy weather. Once, during a typhoon, a float jammed in the “safe” position, leaving the crew blind to a rising level. It took hours of careful work (and a lot of cursing) to free it up. That’s why we insist on using cryogenic-grade materials like 316L stainless steel and Invar—anything less, and you’re asking for trouble.

Sensor Tech Rundown: The Good, the Bad, and the Icy

Mechanical Float Switches: Simple and direct, but prone to icing and “chatter” from sloshing. They need stilling wells and anti-icing features. Proof-testing is easy, but maintenance is constant.

Capacitance Point Sensors: Compact, with no moving parts. They sense the difference in dielectric constant between LNG vapor and liquid. But frost or ice can fool them, and they need regular calibration and anti-icing measures.

Guided-Wave Radar (GWR): My personal favorite for cryogenic level measurement. GWR sends microwave pulses down a probe, giving precise readings even with vapor present. Still, the probe must be protected from ice build-up, and only cryogenic-rated materials will do.

Free-Space FMCW Radar: Non-contact and robust, but the antenna can ice over or get blocked by heavy vapor. Needs marine and cryogenic approvals, and regular inspection.

Ultrasonic Point Sensors: No moving parts, but unreliable in LNG due to vapor cushions and temperature gradients. I’ve rarely seen them used successfully for high-high level alarms.

Thermal Conductivity/Cryogenic Switches: These detect rapid heat loss in liquid versus gas. They’re tough, but response time and material selection are critical.

Differential Pressure (DP) Systems: Rarely used for independent HHL alarms—impulse lines can freeze or block. But they sometimes add diversity in voting setups.

Voting Logic: Why One Brain Isn’t Enough

Here’s a truth every LNG officer learns: “You wouldn’t trust one thermometer for a whole hospital—why do it with alarms?” (Osheyor Gidiagba et al., 2023). That’s why we use voting logic. In pirate-speak: “Arrr, it takes two (or three) brains to call the alarm!” The most common setup is 2oo3 (two out of three): if two of three sensors agree, the alarm triggers. This guards against one rogue sensor—say, a radar fooled by a layer of frost, or a float stuck by ice—shutting down the cargo operation for no reason.

Redundancy: Mixing Tech to Dodge Disaster

Redundancy isn’t just about having backups—it’s about diversity. I’ll never forget the time a vendor tried to sell us three identical sensors for a critical alarm system. No dice! If one fails due to a common cause (like icing), the others probably will too. That’s why we mix sensor types—maybe a mechanical float, a guided-wave radar, and a capacitance probe—all with independent wiring and power. This way, we dodge what’s called “common-mode failure.”

Material Matters: Cryogenic-Grade or Bust

Choosing “cryogenic-grade” isn’t just marketing fluff. Materials like Invar and 316L stainless steel are proven to survive the cold without cracking or warping. Every sensor, cable, and junction box must be rated for the extreme environment, or you risk silent failures—the worst kind in LNG operations.

Short Horror Stories from the Field

That time a mechanical float jammed during a typhoon—leaving the crew in the dark as the tank filled dangerously close to the brim.

The legend of the radar sensor fooled by a perfect layer of frost, sending a false “tank full” alarm and shutting down cargo operations for hours.

One captain’s “inspection” method: tapping the tank and listening for echoes. (Not recommended, but it shows how much we rely on trustworthy alarm systems!)

(3) Tales of ESD: When Alarms Trigger the Big Red Button

Real-World Scenario: The Night a Routine Test Tripped ESD-2

It was supposed to be a standard proof test—just another checkbox in the LNG carrier’s safety management routine. But as the independent high-high level (HHL) alarm was simulated for its six-monthly test, something unexpected happened. The alarm output, designed to be completely independent and fail-safe, triggered the Emergency Shutdown System (ESD-2). In an instant, both the ship and the shore terminal went into full lockdown. Cargo pumps stopped, valves slammed shut, and loading arms froze. The entire operation ground to a halt, and the event log was flooded with time-stamped alarms. The aftermath was a scramble of phone calls, incident reviews, and a hard lesson in the chain reactions that can follow a single trip.

Understanding ESD-1 and ESD-2: What Gets Shut Down and Why

On LNG carriers, emergency shutdown is not a single event—it’s a carefully layered defense. ESD-1 is the local guardian: if a high-level alarm or HHL sensor detects a dangerous rise in tank level, it immediately stops cargo pumps and closes valves on the ship. ESD-2, on the other hand, is the big red button that coordinates a full stop between ship and terminal. It’s triggered by critical events like HHL activation, loss of communication, or manual intervention, and it halts all transfer operations on both sides. According to the IGC Code Chapter 15.3, both systems must receive clear, independent signals from the alarm systems, and both must provide audible and visual alarms in the Cargo Control Room (CCR) and on the bridge.

When either ESD-1 or ESD-2 is tripped, the first call usually goes to the Cargo Officer—but the ripple effect quickly involves the terminal operator, ship’s master, and sometimes the port authority. Everyone wants to know: was it a real overfill event, a sensor glitch, or a test gone wrong?

Behind the Curtain: Automatic Shutdown and the Domino Effect

The integration between alarm systems and ESD logic is both a marvel and a headache. When an HHL alarm output is received, the ESD logic solver (often a SIL 2 PLC) springs into action:

Cargo pumps are stopped automatically.

Tank filling and discharge valves are closed—sometimes within seconds.

Ship/shore link is signaled to halt transfer at the terminal.

Annunciators and event logs capture every action, with precise time stamps for later review.

This chain reaction is by design—functional safety standards like IEC 61508 and 61511 require that a single credible failure (like an overfill) leads to a safe state. But the domino effect can be disruptive. A false trip during cargo ops can cost hours of delay, require full system resets, and trigger a cascade of incident reports.

Integration Headaches: Getting Alarms and ESD to Agree

Making alarm outputs “talk” to ESD systems is a technical challenge. Each system must be fully independent—separate sensors, wiring, power, and logic. But they must also agree on when to shut down. Voting logic (like 2oo3) helps reduce false trips, but integration can be tricky:

Signal delays between alarm and ESD logic can cause out-of-sequence shutdowns.

Testing protocols must ensure that simulated alarms don’t accidentally trigger real shutdowns—unless that’s the test goal.

System upgrades or sensor replacements can introduce mismatches in logic or timing, leading to unexpected trips.

I’ve seen terminals and ship operators spend hours tracing a single missed signal—only to find a loose terminal or a software update that changed the shutdown sequence.

OSG/Terminal Nightmares: Confessions from the Deck

Ask any cargo officer or terminal operator about their worst shift, and you’ll hear stories of alarms missed in the noise, or ESD trips that came out of nowhere. During busy cargo operations, it’s easy to overlook a flashing light or a brief siren—especially when dozens of alarms are active. That’s why operational guidelines stress the importance of clear, unambiguous alarms, regular drills, and strict adherence to checklists.

Despite all the technology, there’s still a human element. As Saraf et al. (2024) put it:

"True safety is the sum of all the systems you barely notice—until you really need them."

Why Audible and Visual Alarms Aren’t Enough

Even with the best alarm systems, chaos can creep in. Audible and visual alarms are essential for immediate awareness, but they can be missed, misunderstood, or ignored in the heat of operations. That’s why the integration with ESD systems—and the automatic, time-stamped response—is so critical. The system doesn’t wait for human intervention; it acts, logs, and protects, even if it means stopping everything in its tracks.

In LNG carrier safety management, every alarm, every shutdown, and every log entry is part of a larger story—a story where functional safety and emergency shutdown systems work together to prevent the unthinkable.

(4) Lifecycles and Loopholes: The Never-Ending Job of Staying Safe

When it comes to LNG carrier safety management, I’ve learned that the job never truly ends. The functional safety lifecycle—spanning from system selection to decommissioning—demands constant vigilance, regular proof testing, and a healthy respect for paperwork. If you think the alarm systems are “set and forget,” think again. The reality is far more hands-on, and sometimes, a little absurd.

Proof Testing: Rituals, Routines, and the One Time We Skipped It

Proof testing of high-level (HL) and high-high level (HHL) alarms is not just a regulatory checkbox—it’s a ritual that keeps LNG carriers safe. According to IEC 61508/61511, these safety instrumented systems must be proof tested every 6–12 months to maintain their SIL 2 certification. On our vessel, this means scheduling, prepping, and executing tests like clockwork. The process involves simulating overfill conditions, verifying sensor responses, and confirming that alarms trigger both visually and audibly in the CCR and bridge.

But what happens if you skip a proof test? I’ll never forget the officer who decided to “save time” by skipping a wet test, only to discover—during a live cargo operation—that the HHL sensor was stuck due to ice. The resulting scramble was equal parts panic and slapstick, with crew members frantically checking wiring while the chief engineer muttered about “never trusting shortcuts.” It was a harmless outcome, but a stark reminder: regular proof testing is not optional. As Barbara & Garcia-Molina (1987) put it,

“Maintenance isn’t glamorous, but it’s what keeps heroes from becoming headlines.”

Lifecycle Approach: From Kit Selection to Chasing Calibration Stickers

The functional safety lifecycle for LNG carrier alarms starts long before the vessel leaves the yard. Selecting the right sensor technology—mechanical float, capacitance, radar, or thermal—is just the beginning. Each choice must meet IGC Code, SOLAS, and Ex (IEC 60079) requirements, and be robust enough for -163°C LNG service. But the real challenge comes years later, when you’re hunting down a vendor for a missing calibration sticker or trying to source a replacement part for a discontinued sensor.

Lifecycle management means tracking every change: configuration updates, software patches, and even the serial numbers of replaced components. Documentation is your lifeline. Without up-to-date logs, you risk losing your SIL certification and, more importantly, your margin of safety.

‘Permit to Work’: More Paperwork Than Cargo

Bypassing an alarm for maintenance is sometimes necessary, but it’s never taken lightly. The “permit to work” process is infamous for its paperwork—sometimes it feels like more forms than cargo manifests. Every bypass must be justified, risk-assessed, and signed off by multiple officers. Restoration protocols are strict: alarms must be tested and reinstated before cargo operations resume. The loophole here is human error—forgetting to restore a bypassed alarm can be as dangerous as the fault itself.

Drill or Be Drilled: Operator Training Tales

Operator training is where theory meets reality—and sometimes, chaos. We drill alarm responses before every cargo operation, running through checklists and simulated failures. But not every drill goes as planned. I once watched a junior officer “test” a bypassed alarm, convinced it would trigger. It didn’t, of course, because it was still bypassed. The lesson? Training must include not just procedures, but the critical thinking to spot when a system isn’t in its normal state.

Documentation Disasters: Logs, Checklists, and Certificates

Keeping documentation intact on an LNG carrier is a battle against salt spray, time, and inattentive crewmates. Every proof test, bypass, calibration, and Ex inspection (per IEC 60079-17) must be logged. Missing or illegible records can mean failed audits—or worse, missed warning signs. I’ve seen checklists dissolve in the rain, calibration certificates lost in the galley, and logs written in handwriting only the author could decipher. The only solution is relentless discipline: digital backups, redundant logs, and regular reviews.

Proof test interval: Every 6–12 months (standard for SIL 2)

Mandatory alarm checks: Before every cargo operation

Bypasses: Strictly managed under permit-to-work and restoration protocols

Documentation: Logs, checklists, and Ex certificates must be complete and accessible

In LNG carrier safety management, the never-ending job is to stay ahead of both technical failures and human loopholes. Regular proof testing, a robust lifecycle approach, and relentless documentation are the only ways to keep the system—and everyone onboard—safe.

(5) Wildcards on Deck: The Unpredictable Side of Overfill Safety

Even with the most advanced LNG carrier alarm systems, the unpredictable always finds a way to sneak aboard. As someone who’s spent years reviewing high-level alarm (HLA) and independent high-high level (HHL) systems, I’ve learned that real-world operations rarely follow the script. Regulations, best practices, and technical redundancy are our foundation—but it’s the wildcards that keep every cargo officer and engineer on their toes.

Garden Hose Solution: When Ingenuity Meets Desperation

One of the most memorable stories I’ve heard from the LNG fleet is about a legendary chief engineer who, frustrated by a stubborn level alarm refusing to trigger during a proof test, grabbed a rubber garden hose. He ran it from a deck hydrant, snaked it through the tank dome, and—against every rule in the book—used water to simulate rising LNG. The alarm finally sounded. The lesson? Never underestimate the lengths a determined crew will go to prove a point (or a sensor). Of course, this is a classic “don’t try this at home” moment, but it highlights the creativity and resourcefulness that sometimes bridge the gap between theory and reality.

Hypothetical Disaster: If All Alarms Failed at Once

Imagine the nightmare: you’re mid-transfer, and every alarm—HLA, HHL, gas detection, emergency shutdown—goes silent. The redundancy built into LNG carrier alarm systems (like 2oo3 voting logic, independent cabling, and separate power sources) is specifically designed to prevent this. But what if, by some freak coincidence, all layers failed? It’s the kind of scenario that turns a routine drill into a lifeboat launch with your career on the line. While I’ve never seen a total blackout, the possibility is why we drill relentlessly, maintain strict permit-to-work controls, and never bypass alarms without a risk-assessed plan. It’s also why functional independence and diversity in sensor types are non-negotiable.

Alarm Fatigue: When Safety Becomes Background Noise

There’s a hidden danger in overfill safety: alarm fatigue. When systems are too sensitive or poorly maintained, false positives become common. Crew members start to tune out the beeps and flashes, assuming it’s “just another glitch.” This complacency can be deadly. I’ve seen logs where nuisance alarms outnumber real alerts ten to one. That’s why regular proof testing, calibration, and system reviews are essential—not just for compliance, but to ensure that when an alarm does sound, it gets the urgent attention it deserves.

Environmental Hazards: Salty Air, Seagull Sabotage, and the Worst Timing

The marine environment is relentless. Salty air corrodes connectors, condensation creeps into junction boxes, and power instability can cause nuisance trips. But sometimes, the wildcards are feathered. As one LNG cargo officer told me:

'No one ever writes a procedure for the time a bird lands on your level sensor.'

It sounds like a joke, but animal interference is a real issue. I’ve seen sensor drift blamed on everything from seagull droppings to nesting attempts. And yes, alarms have a knack for going off at the worst possible moment—during critical cargo operations, or when the bridge is short-staffed. That’s why robust environmental ratings (IP66/67), regular inspections, and marine-grade materials are more than just regulatory checkboxes—they’re survival tools.

Outsmarting Disaster: Crew Improvisation—Brave and Risky

When systems falter, it’s often the crew’s quick thinking that averts disaster. I’ve heard of officers using handheld gas detection meters as a backup when fixed systems were under maintenance, or rigging temporary power supplies to keep alarms online during generator changeovers. These actions are both brave and risky—highlighting the need for clear procedures, thorough training, and a culture where reporting issues is encouraged, not punished.

Redundancy is mandated: Voting logic (like 2oo3), separate power sources, and independent cabling are standard for a reason.

Environmental exposure complicates everything: From corrosion to animal interference, no two days are the same.

Alarm fatigue is real: Too many false alarms can dull even the sharpest crew’s response.

Resourcefulness is key: Sometimes, it’s the crew’s ingenuity—within safe boundaries—that keeps the ship and cargo safe.

In the world of LNG carrier overfill safety, the wildcards are ever-present. Whether it’s a garden hose workaround, a hypothetical total system failure, or the simple unpredictability of nature, the human element remains both the greatest risk and the greatest asset on deck.

(6) Looking Forward: Are LNG Alarm Systems Future-Proof?

As I look ahead, standing on the bridge of an LNG carrier or reviewing the latest gas detection technology in a shipyard, the question that keeps surfacing is: are our LNG alarm systems truly future-proof? The industry has come a long way, layering redundancy, independence, and regular proof testing into every safety feature. But with technology evolving at breakneck speed—and the regulatory landscape always shifting—the future feels both promising and uncertain.

The AI Revolution: Smarter Alarms, Fewer False Positives?

Artificial intelligence and machine learning are the buzzwords echoing through every maritime conference and vendor pitch. The promise? Smarter LNG carrier alarm systems that can sift through sensor data, learn normal patterns, and cut false alarms by as much as 30%—an industry goal that would make every cargo officer’s life easier. Imagine a system that recognizes the difference between a sloshing-induced spike and a genuine overfill event, or one that can predict sensor failure before it happens. These tools could transform gas detection technology, making alarms more reliable and less likely to cry wolf.

But there’s a catch. As much as I appreciate the potential of AI, I can’t ignore the risks. Could these systems override human decisions in a crisis? Would we trust a black-box algorithm to decide when to shut down cargo pumps or close valves? The best safety features are only as good as the crew’s confidence in them. As one LNG ship superintendent told me,

“The safest system is the one your crew trusts—and can actually fix at sea.”

No matter how advanced our alarms become, they must remain transparent, understandable, and—critically—repairable by the people onboard.

Predictive Maintenance: Hype vs. Reality

Predictive maintenance is another hot topic. In theory, self-diagnosing sensors and smart analytics should mean fewer surprises and less downtime. In practice, most LNG carriers still scramble for spares every quarter, racing to complete regular proof testing and keep up with paperwork. Technology refresh cycles in this space are typically five to ten years, meaning today’s “cutting-edge” system can feel outdated long before it’s due for replacement.

Still, I see real value in the move toward predictive maintenance. If we can catch a failing sensor before it triggers a false alarm or, worse, misses a real one, we’re ahead of the game. But the reality at sea is messy—salt, frost, vibration, and the occasional seagull can all wreak havoc on even the most robust gas detection technology. The next generation of sensors needs to be not just smart, but also tough enough for the harshest conditions.

Regulatory Evolution: A Moving Target

Regulations like the IGC Code, SOLAS, and IEC/ATEX standards are always evolving. While this can feel like a moving target for ship operators, it’s not always a bad thing. Each update brings lessons learned from real incidents, new technologies, and better understanding of risk. The challenge is keeping up—ensuring every LNG carrier’s alarm system is not just compliant on paper, but genuinely effective in practice.

Zero Incidents or Zero Risk?

There’s a difference between aiming for zero incidents and believing we can achieve zero risk. The LNG industry’s culture of redundancy, regular proof testing, and independent safety features shows we know perfection is impossible—but we can get close. The goal is a system that fails safe, alerts the crew early, and gives everyone the tools to respond quickly and effectively.

My Wishlist: Human Factors, Less Paperwork, and Frost-Proof Sensors

If I could shape the future of LNG carrier alarm systems, I’d start with more human factors training—making sure every officer understands not just what the alarms mean, but how to act on them. I’d push for less paperwork and more intuitive digital logs, so crews spend less time filling forms and more time focusing on safety. And, perhaps most importantly, I’d love to see a sensor that can survive both the coldest frost and the most persistent seagull.

In the end, future-proofing LNG alarm systems isn’t just about smarter technology or stricter rules. It’s about building systems that crews trust, that adapt to changing risks, and that keep evolving—just like the sea itself. The journey continues, and so does our commitment to safety.

TL;DR: If you crave a glimpse inside the real-life safeguards (and surprises) behind LNG carriers’ overfill alarms, you’ll find stories, technical insights, and first-hand lessons right here. In short: high-level vigilance, plenty of backups, and just enough humor to keep disaster at bay.

Comments

Post a Comment