It was 0200 hours off the coast of Singapore when I first realized: a cargo pump isn’t just machinery—it's the thin line between routine transfer and maritime mayhem. In my three decades afloat, the Ebara 16EC-24 pump has saved the night and my nerves more times than I can count. Forget the dry textbooks—what matters is the living, breathing rhythm of the CCR, the hiss of cryogenic vapour, and the dance of digits in the Integrated Automation System (IAS). This isn't just gear; it's stewardship. Let me draw back the curtain on the mindsets, oddball lessons, and field-tested rituals that define mastery of LNG cargo pump operations.

Pumps, Pressure, and Personalities: The Living System of LNG Cargo Operations

Over three decades at sea, I’ve learned that the true heart of an LNG carrier beats not in the engine room, but in the cargo tanks—where the Ebara 16EC-24 pump quietly orchestrates the transfer of cryogenic cargo. This isn’t just a machine; it’s the pulse of every LNG cargo operation, a living system where steel, pressure, and human discipline converge. As Captain James Devlin once put it,

"The heartbeat of LNG transfer isn’t the steel underfoot, but the discipline in your routine."

The Ebara 16EC-24: More Than Metal

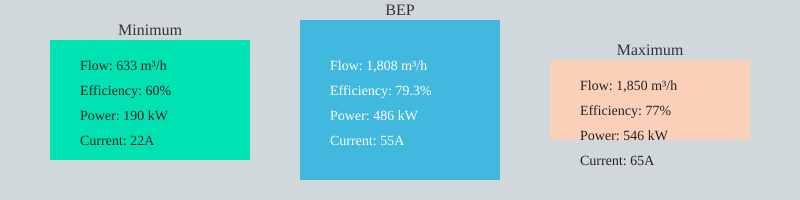

The Ebara 16EC-24 pump is engineered for the extreme—moving LNG at temperatures below -160°C, within a normal flow range of 633–1,850 m³/h, and hitting its Best Efficiency Point (BEP) at 1,808 m³/h. But numbers alone don’t tell the story. Each pump has its quirks. I remember a night when a subtle drift in the motor ammeter—just a few amps above normal—hinted at a looming suction blockage. The pump was ‘talking’ to us, and only by knowing the system intimately did we catch the problem before it became a crisis. In LNG cargo pump operation, these small signs are everything.

Machinery Quirks: Listening to the System

Every Ebara 16EC-24 is unique. Sometimes, the only warning of trouble is a gentle increase in motor current or a slight drop in discharge pressure. The Integrated Automation System LNG (IAS) is the vigilant conductor, centralizing all control, alarms, and monitoring. It tracks discharge pressure (always above 200 kPa), motor current (never over 65A, or the pump trips), and flow. But the IAS is only as good as the operator watching it. I’ve seen how a distracted glance or a missed alarm can turn a minor quirk into a major headache.

The Human Element: Discipline Over Improvisation

There’s a temptation, especially under pressure, to improvise. Early in my career, I nearly learned the hard way. During a busy transfer, a misstep in the startup sequence almost led to a dry run—a cardinal sin for cryogenic cargo pump features. The Ebara 16EC-24 relies on LNG for cooling and lubrication; running dry, even briefly, risks catastrophic damage. It was strict adherence to procedure—checking tank level (>1000mm), verifying discharge valve position (never less than 18% open), and respecting restart limits (no more than 3 consecutive, then a 30-minute wait)—that saved us. In LNG cargo pump operation, there’s no room for shortcuts.

Cryogenic Cargo: Every Operation Is a New Puzzle

Each LNG transfer brings its own set of variables: tank levels, shore rates, temperature swings, and unexpected pauses. Cryogenic cargo is unpredictable. Even with the best equipment, the real challenge is adapting in real time. The IAS helps by wrangling numbers, alarms, and trends, but it’s the operator’s situational awareness that makes the difference. I’ll never forget my first midnight watch, misreading a minor pressure dip as a routine fluctuation. That lesson—learned in the quiet tension of the CCR—taught me that every data point matters, especially when the cargo is colder than Antarctica.

The Living System: People, Pumps, and Procedures

The Ebara 16EC-24 pump and the Integrated Automation System LNG form the backbone of safe, efficient cargo transfer. But it’s the personalities in the CCR—their vigilance, discipline, and willingness to learn—that turn a complex system into a living, breathing operation. We rely on clear KPIs: maintaining flow above 633 m³/h, watching for current spikes, and never exceeding four restarts per hour. But above all, we rely on each other, and on the procedures that have been written in sweat, experience, and the occasional near-miss.

In LNG cargo pump operation, every transfer is a test of both technology and teamwork. The Ebara 16EC-24 isn’t just metal—it’s the pulse of the ship, and the living system that keeps the world’s energy moving safely across the sea.

The Anatomy of Perfection: Features, Limits, and the Beating Heart of the Ebara 16EC-24

Over three decades at sea, I’ve learned that the Ebara 16EC-24 isn’t just a pump—it’s the silent workhorse and the true heart of LNG cargo operations. Its design, features, and operational boundaries are the difference between a smooth transfer and a nightmarish emergency. Let’s break down what makes this pump a masterpiece, why its limits matter, and how respecting its “red lines” is non-negotiable for anyone who values safety (and their sanity).

Deconstructing the Pump: Submerged Induction Motor and Thrust Equalizing Mechanism

The Ebara 16EC-24 is a fully submerged centrifugal pump, meaning its induction motor sits directly in the LNG, cooled and lubricated by the very cargo it moves. This eliminates the risk of ignition and the headaches of mechanical seal failures—one less thing to keep you up at night. Its patented thrust-equalizing system is the unsung hero, balancing axial loads and extending bearing life. In practice, this means fewer breakdowns, less downtime, and a pump that just keeps running—provided you treat it right.

Performance Stats at a Glance: Flow, Pressure, and the Ammeter’s Red Line

Here’s where the numbers matter. The Ebara 16EC-24’s performance envelope is defined by three critical flow rates:

Minimum continuous flow: 633 m³/h (never go below this, or risk overheating and bearing damage)

Best Efficiency Point (BEP): 1,808 m³/h (the sweet spot—maximum efficiency at 79.3%)

Maximum design flow: 1,850 m³/h (don’t push beyond this, unless you enjoy alarms and angry chief engineers)

The motor’s maximum current is 65A—cross that “red line” for more than 5 seconds, and you’ll trip the pump. Power peaks at 546 kW at 120% capacity, but normal operation should keep you well below that. The motor is rated at 6,600V, 597kW, 60Hz—a beast, but one with clear boundaries.

Table: Ebara 16EC-24 Technical Specs and KPIs

Maximums and Minimums: The Hard Limits

Ignore these at your peril:

Never run below 633 m³/h—bearings will overheat, and you’ll be writing incident reports.

Never exceed 1,850 m³/h—risk of vibration, cavitation, and pump damage skyrockets.

Never exceed 65A for more than 5 seconds—the trip will save the pump, but not your pride.

Restart limits: 3 consecutive starts, then a 30-minute wait; max 4 starts per hour.

Why Working Too Close to the Limits Gets You in Trouble

I’ll never forget the time a colleague tried to start the pump with the tank level just under 1,000mm. The interlock saved the day, but his ego took a hit. These boundaries aren’t arbitrary—they’re hard-won lessons, built into the system to protect both the equipment and the crew.

Real-World Rundown: Above BEP, Below Minimum Flow, and Valve Position Follies

Above BEP: The pump strains, efficiency drops, and vibration increases—think of it as running a marathon in steel boots.

Below Minimum Flow: Bearings overheat, the motor whines, and you’re one step from a breakdown.

Valve too closed: High pressure, low flow, and a risk of tripping on high current.

Valve too open at start: Sudden current spike—watch that ammeter!

“Operating at the pump’s sweet spot isn’t just efficiency—it’s peace of mind.” — Chief Engineer Rajiv Sukumaran

Pump logs are your best friend for diagnosing trouble—rising start-up currents often mean bearing wear or suction issues. In the world of LNG, the Ebara 16EC-24’s features and operational limits aren’t just numbers; they’re the rules that keep the heart of the ship beating strong.

Safety Rules, Rituals, and the Oddball Mistake: How Procedural Discipline Saves More Than Face

Over three decades at sea, I’ve learned that the difference between a smooth LNG cargo transfer and a near-miss often comes down to one thing: procedural discipline. The Ebara 16EC-24 cargo pumps are marvels of engineering, but even the best equipment is only as safe as the protocols that govern its use. In LNG cargo safety protocols, there’s no room for improvisation—every step, from the cargo pump operational checklist to the final shutdown, is a ritual that saves more than just face. It saves lives, cargo, and the pumps themselves.

Golden Rules: The Non-Negotiables

No dry runs: Never operate the pump without LNG covering the suction—dry running destroys bearings and seals in minutes.

Never under 633 m³/h, never over 1,850 m³/h: These are the bookends of safe operation, straight from Ebara’s manual and enforced by the IAS. Stray outside, and you risk cavitation or overload.

Ammeter in the green: Watch the motor current like a hawk. If you’re edging toward 65A, you’re flirting with a trip and possible pump damage.

These rules are for everyone—seasoned pros and greenhorns alike. They’re not just guidelines; they’re the backbone of every LNG cargo safety protocol.

Common Safety Bumps: The Oddball Mistake

Let me share a story: One night, a discharge valve stuck at 17%—just below the 18% threshold required for pump start. The IAS refused to give start permission, and a cascade of interlocks followed. Alarms blared, the CCR filled with tension, and for a moment, it felt like chaos. But the system worked as designed. The cargo pump operational checklist Ebara requires that the discharge valve be at least 18% open to prevent deadheading the pump. That “minor” detail saved us from a potentially catastrophic overpressure event. Most incidents I’ve seen trace back to skipped steps or complacency—never improvise.

IAS and ESD: Sentinels and Saviors

The Integrated Automation System (IAS) is both friend and enforcer. It monitors every parameter—tank level, pressure, valve position, motor current—and won’t let you cut corners. Sometimes, it feels like an anxiety generator, but I’d rather have a false alarm than a real disaster. The Emergency Shutdown (ESD) system is the last lifeline. If tank pressure drops below 20 mbarg, ESD trips the pump instantly, protecting both crew and cargo. These electronic sentinels are the heart of safety protocols LNG cargo operations demand.

Parameter | Interlock Threshold |

|---|---|

Discharge Valve Position | Not <18% |

Tank Level | >1000mm |

Tank Pressure | >30 mbarg |

ESD Trip | <20 mbarg |

Integrated for early warning |

Checklists: The Ritual That Saves

Every operation starts with a checklist. No matter how late you are for coffee, you never skip the pre-op walkaround. Physical inspection catches what alarms may miss—like a sticky valve or a blocked suction screen. As Chief Officer Maria Jansen once told me:

“Checklists aren’t for forgetful people. They’re for survivors.”

That’s why the cargo pump operational checklist Ebara is gospel on my watch.

Vibration Monitoring Systems: The 3AM Sentry

Vibration Monitoring Systems (VMS) are the silent guardians. A sudden blip on the VMS at 0300 can mean a bearing is about to fail. Early warning lets us shut down and investigate before a million-dollar pump is lost. VMS is now fully integrated with IAS, providing another layer in LNG cargo safety protocols.

Procedural Rituals: Why Discipline Matters

Strict discipline—sometimes bordering on ritual—prevents incidents. Every checklist, every interlock, every alarm is a layer of protection. The system is built so that even the oddball mistake—a stuck valve, a missed reading—triggers a response before real harm is done. Safety protocols LNG cargo operations require aren’t just paperwork; they’re the habits that keep us, the cargo, and the ship safe.

Rising to Mastery: Training, Troubleshooting, and the Never-Ending Climb

Over three decades at sea, I’ve seen firsthand that true LNG cargo pump mastery—especially with the Ebara 16EC-24—comes not from memorizing manuals, but from living the system day in and day out. LNG cargo operator training is a journey, not a sprint, and the best training programs for LNG cargo operators blend theory, hands-on action, and mentorship. Here’s how that climb to mastery unfolds, and why troubleshooting cargo pumps is as much about mindset as mechanics.

The Three Phases of Mastery: Observer, Apprentice, Practitioner

Every operator’s journey starts as the Observer (Days 1-30). This is where you trace pipelines, map out the system, and shadow experienced hands. I always tell new joiners: “Tracing the actual cargo flow on your first day teaches you more than reading the manual for the tenth time.” You learn where the real risks and bottlenecks are—what the diagrams don’t show.

Next comes the Apprentice phase (Days 31-90). Here, you’re hands-on: running checklists, executing start/stop protocols, and learning to spot trouble before it escalates. You’ll make mistakes—everyone does—but under the watchful eye of a mentor, you’ll learn why procedural discipline matters. By now, you’re not just following steps; you’re understanding their purpose.

Finally, as a Practitioner (Day 91+), you’re troubleshooting Ebara 16EC-24 pump issues, optimizing operations, and mentoring others. This is where the never-ending climb truly begins: every operation is a new challenge, every anomaly a lesson.

Hands-On Learning: Why Action Beats Theory

In LNG cargo operator training, practical tasks build confidence. I’ve seen cadets who could recite every pump spec but freeze when the IAS alarm sounded. The best training programs for LNG cargo operators insist on real-world drills: tracing the cargo line, simulating a pump start, and walking through emergency shutdowns. These experiences stick far longer than any classroom lecture.

Troubleshooting: Start with the Obvious

When a pump refuses to start, the temptation is to blame the “gremlins.” But as Second Engineer Arjun Patel put it:

“Every failed start has a story—and a fix if you’re willing to look.”

Checklist-driven troubleshooting cargo pumps is key. Start with the basics: Is the tank level above 1000mm? Is the discharge valve open at least 18%? Are all IAS interlocks cleared? Nine times out of ten, the answer is in the obvious. Only after ruling out the basics do we dig deeper—checking insulation, suction screens, or motor currents.

Top Five Failure Modes—and How We Fix Them

Failure Mode | % Incidents | Resolution | Real-World Example |

|---|---|---|---|

Interlock Prevents Start | 32% | Check IAS alarms, tank level, discharge valve, permissions | CCR alarm: Discharge valve at 15%, not 18%—quick fix, operation resumed |

High Current on Startup | 26% | Inspect suction for blockage, verify tank level | Pump tripped at 68A; found insulation ice at suction screen |

Fluctuating Discharge Pressure | 18% | Throttle discharge, check NPSH, monitor stripping | Pressure swings during stripping—throttling stabilized flow |

Multiple Restarts | 14% | Enforce restart limits, allow cooldown | Operator attempted 5 restarts—mandatory 30-min wait enforced |

Contamination (Water/Steam) | 10% | Immediate shutdown, insulation check, report | Steam leak near motor—shutdown prevented major damage |

Logbook Wisdom: The Power of Granular Records

Keeping detailed logs isn’t just bureaucracy—it’s how we spot trouble before it starts. Recording tank levels, discharge pressures, and start-up currents lets us see trends: a slow rise in startup current might signal bearing wear long before failure. With checklists, our troubleshooting success rate jumps to 92%—without them, it drops to 66%.

Mentoring Moments: Teaching the Next Generation

Mentorship is the backbone of every LNG cargo operator training program. There’s pride in teaching a rookie, but also responsibility. The most common rookie mistake? Rushing through pre-start checks—skipping steps that seem “obvious.” I make every junior trace the system, log every parameter, and explain every alarm. Only then do they earn the right to operate solo.

This tiered approach—Observer, Apprentice, Practitioner—ensures that practical skills, logbook habits, and troubleshooting discipline are built layer by layer. Mastery isn’t a destination; it’s a climb, one operation at a time.

Operational Artistry: Navigating the Fine Points of Flow, Efficiency, and Data-Driven Decisions

After three decades at sea, I’ve learned that true mastery of LNG cargo pumps—especially the Ebara 16EC-24—comes down to a blend of technical discipline and operational artistry. At the heart of this is understanding and applying cargo pump KPIs and key performance indicators for cargo pumps in real time. Finding the Best Efficiency Point (BEP) isn’t just a technical target; it’s like aiming for the bullseye in a storm. Data, discipline, and a willingness to experiment are what get you there.

Flow Rate Management: The Art and Science of LNG Transfer

Managing flow rate during LNG transfer is a balancing act. The Ebara 16EC-24’s BEP is 1,808 m³/h at 79.3% efficiency, with optimal flow at 1,850 m³/h. The minimum safe flow is 633 m³/h. In practice, I’ve found that operating a single pump at or near BEP is almost always more efficient—and gentler on the equipment—than splitting the load between two pumps at lower rates. Unless you enjoy unnecessary wear and tear, this is the rule to live by.

Here’s a snapshot from my logbook, showing how real-world numbers stack up:

Parameter | Value | Notes |

|---|---|---|

Optimal Flow | 1,850 m³/h | Manufacturer’s rated capacity |

Best Efficiency Point (BEP) | 1,808 m³/h | 79.3% efficiency |

Minimum Flow | 633 m³/h | Below this, risk of damage |

Power at BEP | 486 kW | Optimal energy use |

Start-up Current Trend | +1–2A/month | Early sign of bearing wear |

Valve Opening (19% vs. 21%) | Up to 4A lower start current at 21% | Based on my ‘midnight experiment’ |

Pump Performance Testing: The Power of Small Tweaks

One of my most revealing experiences came during a quiet night watch. I decided to test how a small change in the discharge valve opening—moving from 19% to 21%—would affect start-up current. The result? A consistent reduction of up to 4 amps. That’s not just a number; it’s less stress on the motor, less heat, and a longer pump life. As LNG Superintendent Elsa McGregor put it:

“Efficiency isn’t luck—it’s built on careful tweaks and stubborn recordkeeping.”

Every adjustment, no matter how minor, is logged. Over time, these records become a goldmine for optimizing pump performance testing and refining procedures.

Data-Driven Decisions: Trend-Spotting and Predictive Maintenance

Continuous data collection is the backbone of operational excellence. Early anomaly detection—like noticing a steady 1–2A rise in start-up current every month—can point to bearing wear long before a breakdown occurs. The IAS (Integrated Automation System) is my dashboard for spotting these trends. I make it a habit to:

Log every start/stop event with current, flow, and pressure

Compare actuals to expected values weekly

Flag any odd spikes or drifts for immediate inspection

This approach not only prevents surprises but also supports smarter maintenance scheduling and reduces downtime.

Iterative Optimization: A/B Testing and Logging

Optimization is never a one-off. I routinely run A/B tests—like adjusting valve openings or ramp rates—and log the outcomes. Over time, these experiments reveal the best combination of settings for both efficiency and safety. For example, when shore requested a reduced rate, I tested running two pumps at 50% versus one at BEP. The result was clear: one pump at BEP delivered better efficiency and less wear, every time.

Operational artistry with the Ebara 16EC-24 is about methodical flow tuning, relentless data logging, and a culture of continuous improvement. When you treat every cargo operation as a chance to learn and refine, you transform routine tasks into a model of precision and reliability.

Checklists, Case Studies, and Caffeine: Real Tools for Real Life at Sea

After three decades at sea, I can say with certainty: real-world tools—like a robust cargo pump operational checklist—are what keep LNG transfer safe, efficient, and drama-free. Manuals and theory are vital, but when you’re running Ebara 16EC-24 pumps on a rolling deck at 0300, it’s the checklist, the performance log, and a strong cup of coffee that stand between you and a costly mistake. As Third Officer Lena Wu once put it,

"My checklist talks louder than my memory at the end of a double shift."

Sample Checklist: The Pre-Start Ritual That Saved the Day

Let me walk you through a typical pre-start ritual from one of my busiest crossings. The cargo pump checklist is not just a formality—it’s a lifeline. On that night, with eight Ebara 16EC-24s ready and a tight schedule, I ran through the six-point pre-op list:

Tank level > 1000mm

Temperature stable (within vessel limits)

Pressure > 30 mbarg

Motor insulation check (IAS reading, 6.6kV)

Suction screens clear

Discharge valves set and IAS status “Ready”

That night, the insulation check flagged a subtle drop—barely outside normal, but enough to halt the start. We found condensation near a cable gland, which, left unchecked, could have led to a catastrophic short. The cargo pump operational checklist Ebara caught what my tired eyes might have missed. Research shows strict checklist use can cut avoidable errors by 30%—and I’ve seen it firsthand.

Table: Pre-Op Checklists and Performance Logs—Memory Isn’t Enough at 0300

Pre-Start Checklist | Performance Log Fields |

|---|---|

|

|

Logs aren’t just “extra paperwork”—they’re your best ally after a long shift or when auditors come calling. Structured logs support both immediate troubleshooting and long-term review. I’ve solved more than one mystery by tracing a slow drift in startup current or a pressure anomaly back through the logbook.

Case Study: The Fallout When Someone Skips a Step

Here’s a cautionary tale: A junior officer, eager to impress, skipped the insulation check to save time. The pump started, but within minutes, the motor tripped on high current. The root cause? Moisture in the terminal box, which a proper check would have flagged. The fallout: lost time, a delayed transfer, and a stern lesson in LNG transfer procedural discipline. Skipping steps never ends quietly—especially with the Ebara 16EC-24, where procedural discipline is non-negotiable.

Why Logs and Records Are Your Best Ally

Performance logs are more than a regulatory requirement—they’re a diagnostic toolkit. When troubleshooting, I rely on trends: Is the flow rate dropping at the same valve setting? Is startup current creeping up over weeks? These patterns are invisible without logs. During audits, clear records prove compliance with operational limits—like minimum flow (633 m³/h), maximum (1,850 m³/h), and restart protocols. They also support continuous improvement, allowing you to “A/B test” changes and optimize procedures.

FAQ Wild Cards: The Oddest Operator Question

One of my favorites: “Can I run the pump with the discharge valve at 10% to reduce flow?” It’s a fair question—and a teachable moment. The answer is no: running below 18% risks overheating and cavitation. Questions like these reinforce the value of checklists and FAQs. They ensure everyone, from cadet to chief, is on the same page with operational standards.

In the end, checklists, case studies, and caffeine are the real tools that keep LNG cargo operations safe and efficient. The cargo pump checklist isn’t just a formality—it’s the backbone of every successful transfer.

Standards, Growth, and the Never-Ending Voyage of Improvement

After three decades at sea, I can say with certainty that the journey of mastering LNG cargo pump operations—especially with systems as advanced as the Ebara 16EC-24—is never truly finished. The ocean is a relentless teacher, and every cargo transfer is both a test and an opportunity for growth. The foundation of safe, efficient LNG transfer systems is built on two pillars: unwavering adherence to industry standards and a culture of continuous improvement in LNG operations.

Even now, I keep the Ebara technical manual and the latest SIGTTO guidelines within arm’s reach in my bunk. These aren’t just relics or paperwork to satisfy audits—they are living resources. In LNG cargo operations, industry standards from organizations like OCIMF, SIGTTO, DNV, ABS, and Lloyd’s Register are more than regulatory checkboxes. They are your passport through the rigorous world of vettings, audits, and, most importantly, the unpredictable realities of the sea. They shape every checklist, every operational limit, and every emergency response drill. When I see a young officer thumbing through the Cargo Operations Manual or referencing the latest OCIMF bulletin, I know the team is on the right track.

Continuous improvement in LNG operations is not a one-off initiative; it’s a mindset. As Chief Engineer Rajiv Sukumaran once told me,

“Improvement isn’t a project—it’s a habit you build every single voyage.”

Each operation, no matter how routine, is a chance to refine our process, test new ideas, and learn from both success and setback. For example, after noticing a gradual rise in startup currents on one of our Ebara 16EC-24s, we didn’t just log the data—we traced the root cause, adjusted our pre-start checks, and shared the findings across the fleet. That’s LNG operations improvement in action: data-driven, collaborative, and relentless.

The culture onboard is just as critical as the technical framework. Healthy skepticism—questioning “the way it’s always been done”—is encouraged. Mentorship is woven into daily life, whether it’s a chief officer’s two-hour, coffee-fueled debrief or a junior officer shadowing a senior through a tricky stripping operation. Cross-generational knowledge-sharing keeps the team sharp and ensures that best practices aren’t lost to time or complacency. I’ve seen firsthand how a simple tip from a seasoned hand—like adjusting the discharge valve opening by just a few percent during startup—can prevent a cascade of issues down the line.

Resources for improvement are everywhere if you know where to look. The manufacturer’s manual from Ebara, your vessel’s Cargo Operations Manual, SIGTTO and OCIMF bulletins, and the wisdom of your shipmates are all part of the toolkit. Best-practices forums and technical libraries offer a wealth of case studies and troubleshooting guides. But nothing replaces the value of debriefing after each operation, logging what worked, what didn’t, and what could be done better next time. That’s how continuous improvement in LNG cargo operations becomes second nature.

Adhering to up-to-date industry standards preserves both safety and professional credibility. But it’s the ongoing commitment to learning, adapting, and sharing knowledge that transforms a competent operator into a true master of LNG transfer systems. Every voyage, every cargo, and every challenge is a step forward on the never-ending voyage of improvement. In this world, standards are both lifeline and lighthouse, guiding us safely through the complexities of modern LNG operations and ensuring that, no matter how much we know, there is always more to learn.

TL;DR: In a nutshell: True LNG cargo pump mastery fuses technical know-how, relentless safety discipline, data-driven habits, and a dash of humour. The Ebara 16EC-24 is the heart of the operation—but real excellence comes from your process, your mindset, and your willingness to keep learning on every shift.

Comments

Post a Comment